Recirculating Aquaculture System: Better Farming Indoors

Like many industries, the aquaculture sector has many challenges to overcome. With limited space and manual labour available, our fish farmers must embrace technology and automation to increase output. Innovative technological solutions can also help prevent the loss of yield to climate change and unpredictable natural phenomenon.

Recirculating Aquaculture System (RAS)

One such solution is the Recirculating Aquaculture System (RAS), a type of closed containment aquaculture system for fish culture in controlled indoor environments. AVA encourages local farmers to adopt the RAS. Although initial investments are high, farms can achieve higher productivity and the following benefits in the longer term:

- Indoor protection. Fishes are protected against adverse environmental conditions when farmed indoors.

- Space optimisation. Multi-tier tanks allow for highly intensive fish stocking, thus minimising space usage in land-scare Singapore.

- Water resource efficiency. Water could be re-used for fish culturing through multi-level water treatment processes.

- Human resource efficiency. A skid structure can be linked up with an automated system for remote monitoring of water parameters.

Multi-layer turbot farming at Seafarm B.V. The fishes are grown in these vertically stacked tanks, and moved from here through the processing and packing chain entirely using robotics. The farm also uses machinery to clean and maintain these vertical tanks.

Multi-layer turbot farming at Seafarm B.V. The fishes are grown in these vertically stacked tanks, and moved from here through the processing and packing chain entirely using robotics. The farm also uses machinery to clean and maintain these vertical tanks.

Successful Overseas Examples

Several advanced farms overseas have already successfully adopted the RAS. In June 2014, representatives from MND, AVA, and our farming industry learned first-hand how the RAS is employed in aquaculture farms, during a study trip led by Minister of State (MOS) for National Development & Defence, Dr Mohamad Maliki Bin Osman, to Denmark and the Netherlands.

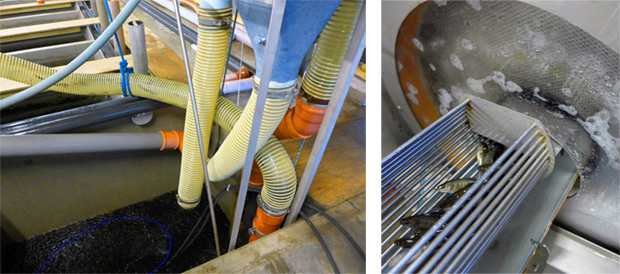

Fingerlings travel through the live fish transfer system to an automated grader for sorting according to size. They then pass through the mechanised vaccination bath before being transported back to their tanks.

Fingerlings travel through the live fish transfer system to an automated grader for sorting according to size. They then pass through the mechanised vaccination bath before being transported back to their tanks.

At Seafarm B.V., a turbot (flat fish) farm, all production and maintenance operations are fully automated and monitored by a centralised software system designed in-house. Only one operator is required to manage the entire facility. The farm owner also believes this prevents fishes from being unduly stressed by human handling, thus improving the quality of the fishes.

Similarly, at Lundby Fish Small Trout Farm, the RAS allows fingerlings to be moved from their tanks through a pump system, graded according to size, vaccinated, and then sorted and segregated into other tanks, entirely by machinery.